Here at EquityEdge Research, we make Small-Cap Investing easy for you by Backing you up with Robust & Full-Fledged Research.

Let’s go!

1. Company Charts

*Comparison charts are Indexed*

Aeroflex Industries Ltd Performance (1yr- up 16%)

Aeroflex Industries Ltd Vs. NSE Nifty

Aeroflex Industries Ltd Vs. NSE Smallcap

2. About the Company

Aeroflex Industries Ltd is a specialized engineering company engaged in the design, manufacturing, and supply of environment-friendly metallic flexible flow solution products. Established with a focus on innovation and quality, Aeroflex has built a strong reputation in the global market for producing stainless steel flexible hoses, assemblies, and related fittings that cater to critical and high-performance industrial applications.

3. Product Portfolio:

Products:

Corrugated Stainless Steel Hoses: Flexible hoses designed for high durability and resistance to corrosion.

Stainless Steel Hose Assemblies: Custom-engineered assemblies that include hoses with end fittings, ensuring compatibility with specific industrial requirements.

Gas Hoses: Specialized hoses suitable for safe gas transfer applications.

Solar Hoses: Hoses designed for solar applications, capable of withstanding high temperatures.

Fittings/End Connections: A variety of fittings and end connections to complement hose assemblies, ensuring secure and efficient connectivity.

Interlock Hoses: Flexible metal hoses with interlocked construction for enhanced flexibility and strength.

High-Pressure Hoses: Hoses are designed to withstand high-pressure applications without compromising on flexibility.

Composite Hoses: Multi-layered hoses suitable for transferring various chemicals and petroleum products.

Services:

Custom Design and Manufacturing: Tailoring flexible hose solutions to meet specific client requirements across diverse industries.

Rigorous Testing: Conducting extensive testing of hose assemblies under various environmental conditions to ensure compliance with international quality standards.

Industry Applications: Providing solutions for sectors such as aerospace and defence, semiconductors, robotics and automation, hydrogen, electric mobility, HVAC, natural gas, steel and metal, petrochemicals, and oil refineries.

Clients

Geographical Presence

4. Management Overview

KMP's Remuneration

If you like the hard work we put in, you can invest in us:

For our Non-Indian audience: You can donate to us through PayPal. Click here.

For our Indian audience, UPI QRs are given below:

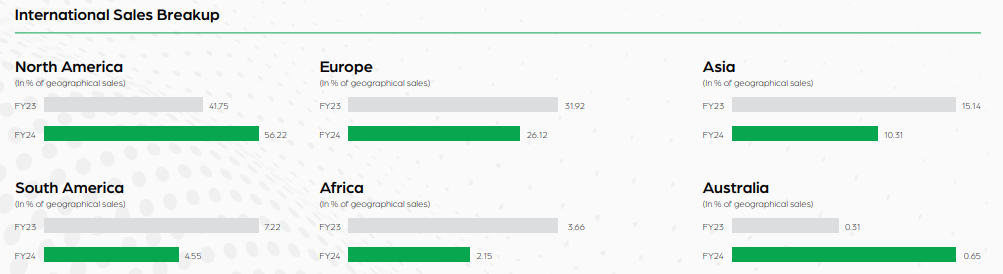

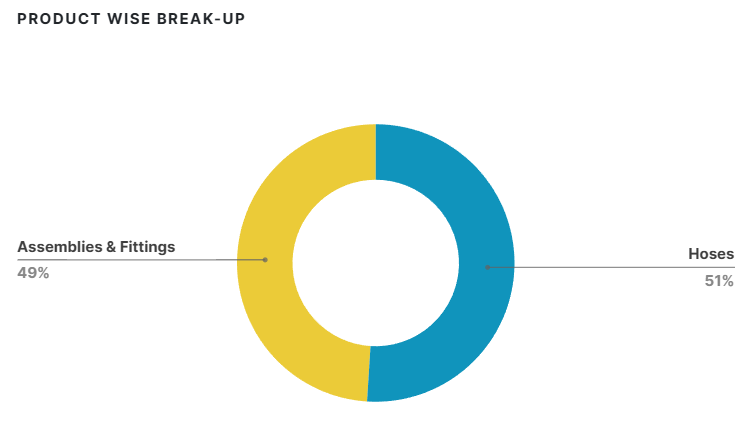

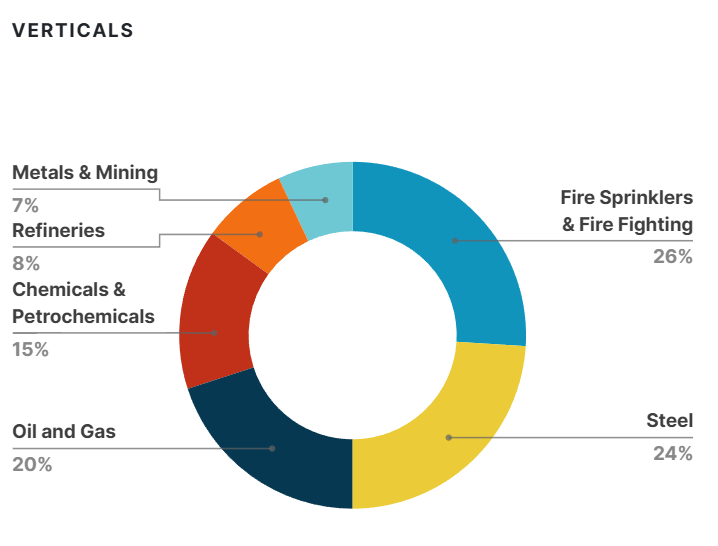

5. Revenue Breakdown:

6. Company’s Financial Analysis:

SALES:

The Sales have grown at a CAGR of ~17% in the past 8 years.

GROSS PROFIT:

Gross Profit has increased at a CAGR of ~16% for the past 8 years.

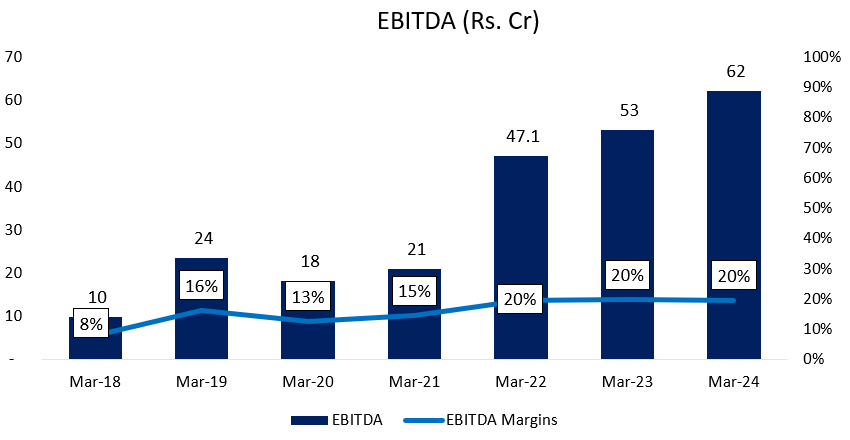

EBITDA:

EBITDA has increased at a CAGR of ~36% for the past 8 years.

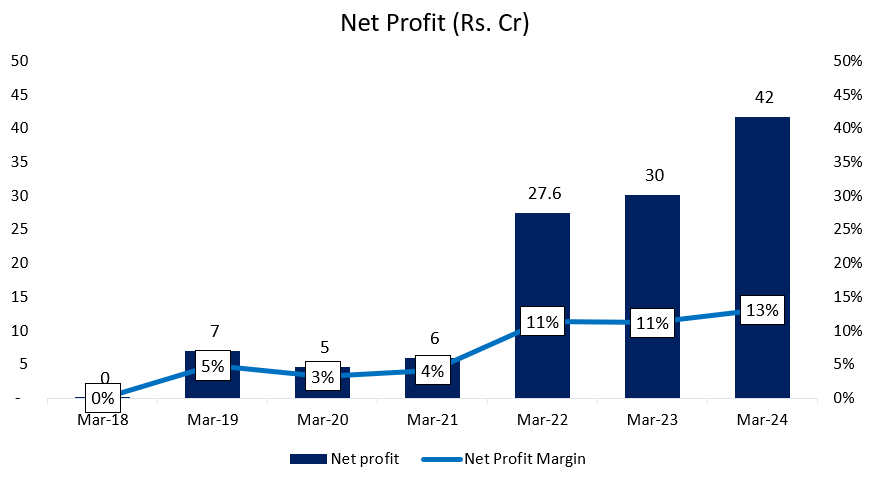

Net Profit Margin %

Net profits have continuously increased at a CAGR of ~198% for the past 10 years.

BALANCE SHEET:

Common-Size Balance Sheet:

Cashflow Statement:

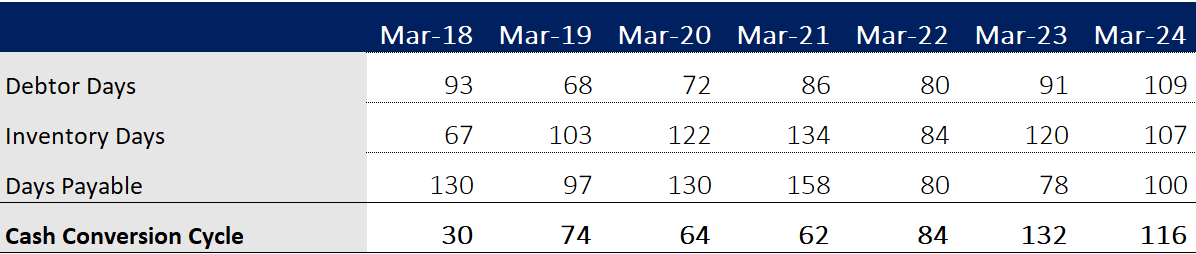

Cash Conversion Cycle:

7. KEY RATIOS:

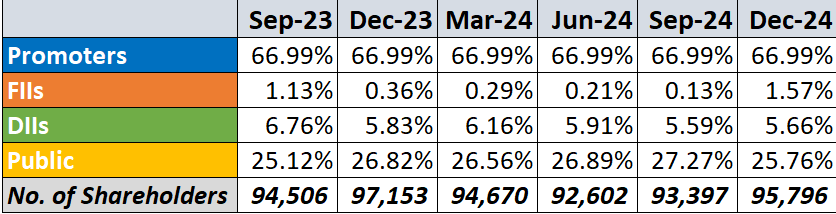

8. Shareholding Pattern:

9. SWOT ANALYSIS:

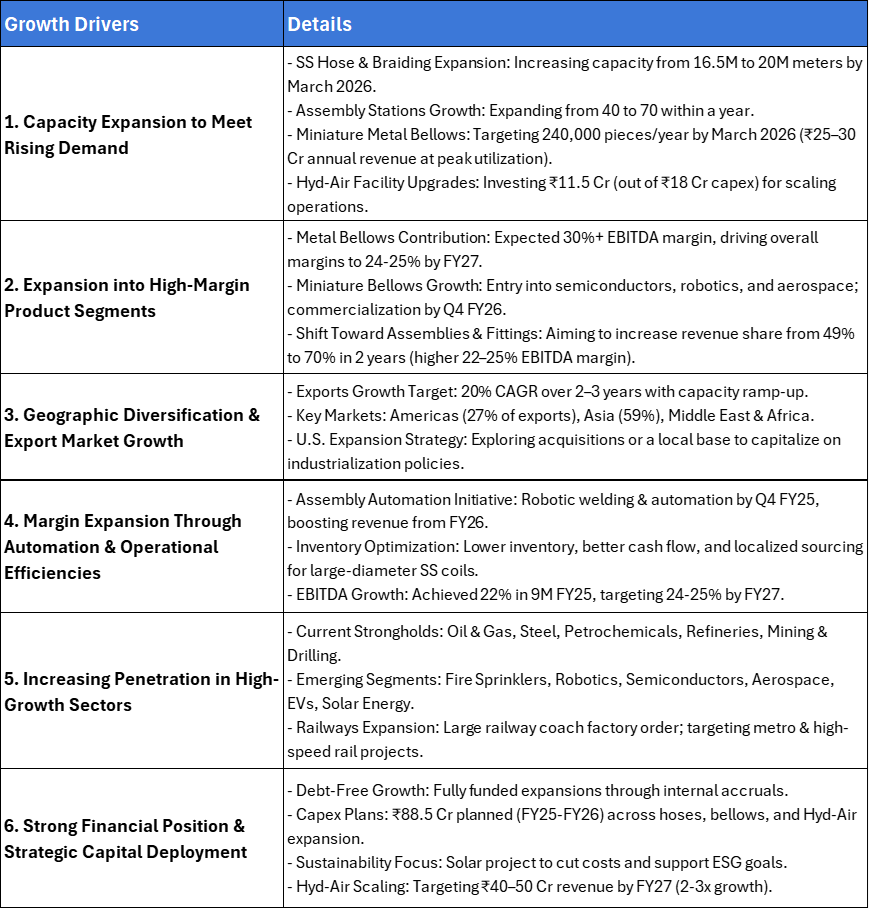

10. Growth Drivers:

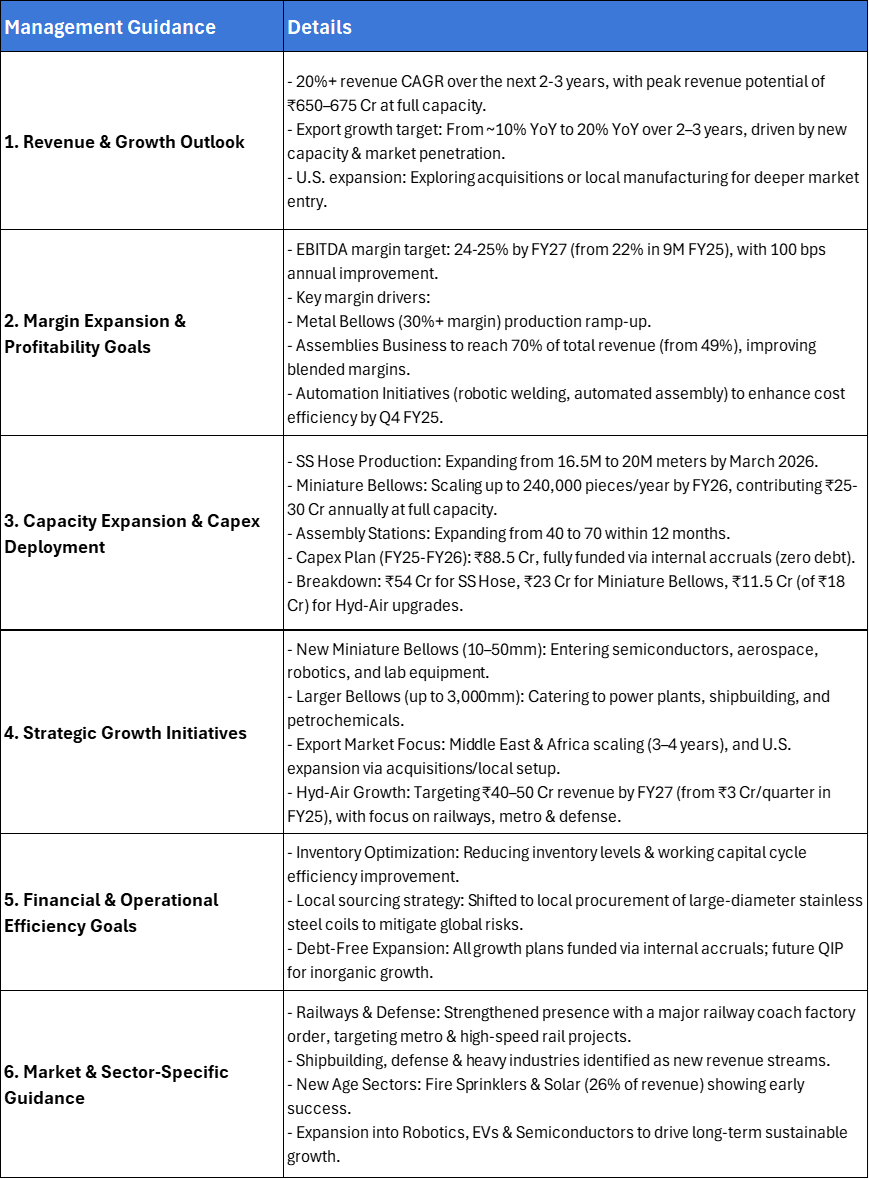

11. Management Guidance:

12. Competitors in the Market

1. Indo-MIM Pvt Ltd

Specializes in precision-engineered components, including parts used in flow control systems.

Strong presence in aerospace, defence, and industrial applications.

2. Bhuwal Insulation Cable Pvt Ltd

Manufactures stainless steel flexible hoses, PTFE hoses, and thermal insulation products.

Caters to industries like chemical processing, oil & gas, and pharmaceuticals.

3. Rajendra Industrial Corporation

Supplies a wide range of stainless steel hoses, pipe fittings, and flanges.

Focused on domestic oil & gas, refinery, and power plant clients.

4. Hydroflex Pipe Pvt Ltd

Offers flexible metal hoses, braided assemblies, and expansion joints.

Known for product customization and adherence to industry standards.

5. Technoflex

Provides metallic and PTFE hose solutions across various Indian industries.

Focuses on cost-effective and durable flow management products.

13. Industry Overview

Global Market Size (2023): USD 25–27 billion

Expected Global CAGR (2024–2030): ~5–6%

Indian Market Size (2023): USD 600–800 million

Expected Indian CAGR: 8–10%, driven by manufacturing push and export demand.

Key Trends:

1. Shift Toward Metal Hoses: Higher demand for stainless steel and PTFE hoses due to durability and resistance to corrosion, chemicals, and temperature.

2. Export Opportunities: Emerging economies and global EPC companies are outsourcing customized assemblies from cost-competitive markets like India.

3. Rise in Clean Energy & Hydrogen: Increasing application of flexible flow solutions in hydrogen, LNG, and renewable energy projects.

4. Defense & Aerospace Demand: Indigenous manufacturing under Atmanirbhar Bharat driving demand for high-spec flow systems.

5. Technological Integration: Smart hose assemblies with sensors and monitoring features are gaining traction in critical industries.

Key Growth Factors:

1. Industrialization & Infrastructure Growth: Rapid growth in sectors like oil & gas, power, chemical, pharma, and food processing is driving demand for reliable fluid transport systems.

2. Make in India & Import Substitution: Increasing domestic manufacturing and push for self-reliance in defence, aerospace, and industrial equipment is fueling demand for high-spec flexible hose assemblies.

3. Export Expansion: India is becoming a preferred hub for customized, certified, and cost-effective hose products, especially in Europe, the Middle East, and North America.

4. Clean Energy & Sustainability: Rising investments in LNG, hydrogen, and solar/wind power projects are creating new use cases for metal hoses and assemblies.

5. Safety & Compliance Requirements: Stricter global standards for fluid transfer systems in critical industries like food, pharma, and chemicals are boosting demand for certified products.

6. Urbanization & Smart Cities: Flexible hose solutions are widely used in HVAC systems, plumbing, and fire safety, gaining importance with real estate and infrastructure development.

Recent Industry Developments:

1. Shift to Metal Hoses: Growing preference for stainless steel corrugated and PTFE hoses due to better life span and resistance to harsh chemicals and temperatures.

2. Technology Integration: Introduction of smart hose assemblies with embedded sensors for monitoring pressure, temperature, and leaks in real-time.

3. Sustainability Initiatives: Manufacturers are adopting eco-friendly production processes, such as solar-powered facilities and recyclable metal use—like Aeroflex.

4. Global Supply Chain Diversification: Post-COVID and geopolitical shifts have pushed OEMs and EPC contractors to diversify sourcing to India, reducing dependency on China.

5. Rising Defense & Aerospace Indigenization: Under Atmanirbhar Bharat, companies are increasingly developing specialized hose systems for use in missiles, aircraft, and submarines.

Thank you for reading till the end! We hope you enjoyed this report.

Researched By- Naresh, Mayank and Vaibhav

All information is sourced from the company's annual reports, GoIndiastocks.in, Screener.in, industry reports and Economy Outlook reports.

Disclaimer: We do not recommend buying or selling any stock. You should consult your financial advisor before buying or selling any financial instrument.

If you like the hard work we put in, you can invest in us:

For our Non-Indian audience: You can donate to us through PayPal. Click here.

For our Indian audience, UPI QRs are given below: